Made like valentino rossi's in the same place... since 1972

Dainese has made custom suits for World Champions like Kenny Roberts Sr., Giacomo Agostini, Eddie Lawson, John Kocinski, Kevin Schwantz, Scott Russel, Max Biaggi, Marco Simoncelli, Nicky Hayden, and of course nine-time World Champion Valentino Rossi.

Clearly, after working with racers such as these for over 40 years, they know how to make custom leather garments. Our Custom Work suits are comprised of many different pieces just like Valentino Rossi's.

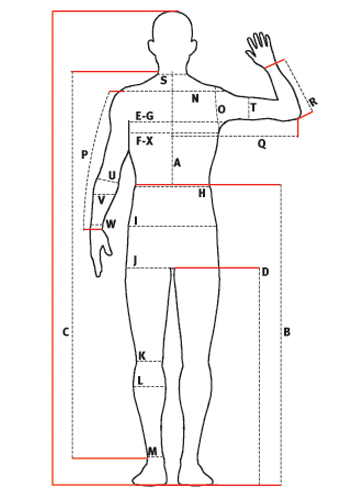

The 'custom' part comes from years of experience and knowing how to interpret the 26 measurements (one being weight) taken by us, and then 'stretching' (morphing) each panel of a standard suit into a panel that will allow the suit to fit together as a unit specifically tailored for each measured rider.

All of this is done in the factory in Molvena, a small village in Northern Italy in an area that is known for fine leather and excellent seamstresses coming from generations of leatherworkers. But the process begins with the client and taking the measurements that Dainese has determined to be the most critical. And only trained Dainese specialists, with years of experience, can take these measurements.

Once the measurements are reviewed and apporoved in Molvena, the process of determining which standard suit to begin with and how best to morph that suit begins. And then the patterns are sent to the computerized leather cutting machines for cutting.

Once an order is created and the garment is approved for production in Molvena, we will recieve 'confirmation' and production is scheduled. When the order's production date arrives, the measurements and photos are then referenced by one of three specialists who will digitally modify (stretch) the panels of an off-the-rack suit to accommodate the specified dimensions of the client. Then all the panels/logos/names/numbers are cut with the appropriate color of leather using laser leather cutting machines. All of the panels/logos/names/numbers and all the necessay accessories such as aluminum shoulder plates and knee and elbow armor (upwards of 200 or more

individual pieces) are placed together in a tray that is then passed off to the seamstresses. The tray of items makes its journey down the sewing machine line where each individual seamstress will do her part. Once completed, the suit is passed off to a technical inspector who will make sure all the seams are properly done, all logos are properly attached, and all the colors correct. Thsi inspector will also clean and condition the suit before wrapping it in protective plastic for shipping. Usually, the finished product is delivered to the client within 3 months of the measuring event, but a longer time is also possible for any number of reasons.

Once delivered, it may be necessary for us to become involved again for an evaluation if the suit does not appear to fit properly. If it is determined that the suit does in fact need adjustment(s), then an After Sales process begins. Of course, we first want to make sure that the client understands how a technical leather garment is designed to fit. Dainese one-piece technical garments are designed through careful study of the body and its movements for the type of activity performed during professional competition. Whenever trying on a Dainese racing suit, the back protector must be inserted, and gloves, boots, and a racing under-suit must be worn together as a unit because the precise fit for the suit was designed with these items in mind. It is also important to understand the riding position on the motorcycle. One-piece suits are designed for super-sport bikes and so the riding position is more extreme: the trunk is

curved, the legs are pre-curved and tighter, and the suit follows the outline of the body while the riding position. This means that the suit should not be comfortable when the rider is standing. I.E. it should be a bit tight in the crotch, and the sleeves and legs should be to short because the correct length and feel will only be felt while in the correct ridding position on an appropriate super-sport bike. The wrinkles that form are perfectly normal and not a sign of excess material. A Dainese two-piece suit is designed more for touring use and therefor will be more comfortable when teh rider is standing and more comfortable in gereral than a one-piece. In this garment form, there may be more wrinkles around teh joints but again, these should no tbe considered as a sign of excess material but only as the fabric required to ensure freedom of movement and comfort while riding.

If a Custom Work garment does not seem to fit properly upon delivery, even after an extensive analysis performed by a trained staff member, then Dainese will take appropriate steps. Our staff will help to make sure that the areas of concern are documented with photos and new dimensions required. This information is then send off to the tailor and forwarded to Molvena for review. There are often several solutions to a fit problem, but in worst case, teh suit will have to be sent back to Molvena for adjustments.

In this case, Dainese will cover shipping costs and also all the costs associated with making any necessary adjustments. While this additional time spent without the custom garment can be frustrating, one must understand that bespoke garments in the clothing industry often require two or three or more visits to the tailor for adjustments. We do our best to get it right the first time, but it is a very difficult and precise process and so sometimes adjustments are necessary.

In this case, we will kindly ask for your patience.